Full EU CBAM Implementation Clock Ticking---The Manufacturing Sector’s Breakthrough Battle

Starting January 1, 2026, the EU Carbon Border Adjustment Mechanism (CBAM) will enter its full implementation stage, imposing additional tariffs on high-carbon industries such as aluminum and steel. Multinational giants like Siemens, GE, Emerson, are tightening carbon emission controls across their supply chains. With the clock ticking, how do the traditional manufacturers make their break through?

As an innovative and forward-thinking corporate citizen, Youthen Metal already certificated by ISO 14001 environmental management system many years ago. Contributing to global carbon reduction is an integral part of our social responsibility. Besides, our flagship product—high-efficiency liquid cooling plates, heatsinks, and thermal management systems—align with the vision of a low-carbon, eco-friendly future, allowing us to contribute to a greener planet. Additionally, reducing energy consumption and minimizing carbon emissions during the manufacturing of our thermal products has always been a consistent objective for our company. And as an important partner to global leaders like Siemens and Emerson, Youthen Metal Technology Co., Limited has taken proactive action. Invested and built a 250 KW PV power station at its rooftop, embarking on a dual path of cost reduction and low-carbon transformation.

This project reduces carbon emissions by over 259 tons annually, significantly cutting energy costs and positioning Youthen Metal as a green manufacturing pioneer in South China!

At the same time, Youthen Metal is collaborating with renowned customers both domestic and international, to jointly develop and manufacture inverters and liquid cooling plates for solar and energy storage systems. We are delighted that our products directly contribute to energy conservation and carbon reduction. And we are already benefiting from the low-carbon now!

battery pack liquid cold plate

Converter heat sink

How Does the PV Project Empower Green Manufacturing?

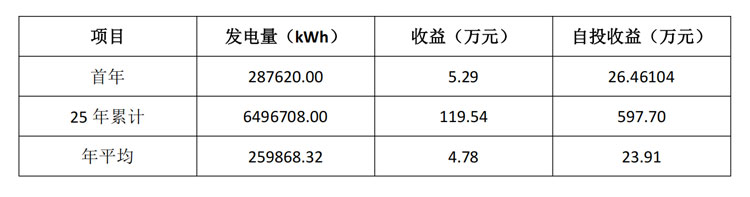

✔ Power Generation Benefits:

Annual output: 259,800 kWh, covering nearly 30% of the company’s production electricity demand.

Lifetime output (25 years): 6.4967 million kWh, equivalent to planting 36,000 trees.

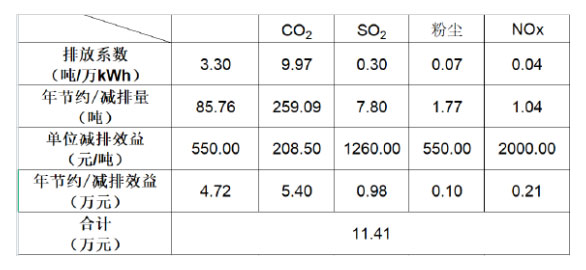

✔ Emission Reduction Value:

Total lifecycle CO₂ reduction: 6,477 tons, meeting Siemens’ supply chain carbon requirements.

CBAM compliance achieved, securing priority access to EU orders.

✔ Comprehensive Benefits

Reduced Heat Gain: The PV-covered roof significantly lowers building heat absorption, decreasing workshop temperatures by 3-5°C and slashing air conditioning energy consumption.

A temperature comparison photo taken by an infrared camera

Peak Shaving & Cost Lock-In: By shifting energy usage to off-peak hours and locking in electricity rates, Youthen Metal Technology achieves substantial cost savings over 25 years.

✔Beyond Emission Cuts: A Competitive Edge

Cost Advantage: 25-year fixed electricity rates shield the company from energy price volatility.

Order Priority: Compliance with Siemens, GE, Emerson and other multinationals' low-carbon standards boosts international order success rates.

Brand Value: Youthen Metal Technology’s green commitment enhances its reputation, unlocking opportunities with new clients and top-tier suppliers.

Youthen Metal Technology: From Compliance to Leadership

Full rooftop coverage with 458 monocrystalline silicon panels (250 kW capacity).

Dongguan’s solar irradiance: 1,150 kWh/m²/year.

Counting 80% of the PV System efficiency: First-year generation: 1,150 full-load hours. 25-year total output: ~6.4967 million kWh.

Photovoltaic layout at Youthen rooftop

Chart of solar Irradiation in Dongguan City

Production Process upgrade: Arrange production aligned with PV generation curves, transformer load reduction by 20%. Peak shaving minimizes grid impact and stabilizes energy costs.

A Milestone in Sustainable Growth

The photovoltaic project is a key initiative by Youthen Metal Technology Co., Ltd. in response to China's "Dual Carbon" goals (carbon peak by 2030 and carbon neutrality by 2060). The "Dual Carbon" strategy advocates for a green, environmentally friendly, and low-carbon lifestyle. The company's management pays close attention to this strategy, and closely follow this national green development policies, achieved both our production lines and manufacturing processes comply with the country's strategic deployment.

Despite the fierce market competition and the long-term challenges of business operations, Youthen Metal Technology Co., Ltd. has consistently remained at the forefront of the industry. Moving forward, the company will continue to enhance product and service quality, providing customers with superior metal product solutions.